From a linear to a circular society.

Half of all greenhouse gas emissions are the result of our linear way of living, according to the Ellen MacArthur Foundation.

That’s why a rapid transition to a more circular society is essential.

Our focus is on plastic packaging.

Closing the loop for plastic packaging

Most plastic packaging placed on the European market is still made from new, fossil-based raw materials.

Although the share of recycled plastic in packaging has increased, it still represents only 9.7 percent of total plastic packaging production in Europe, according to Plastics Europe (2024).

We play a central role in creating a circular economy for plastic packaging from households in Sweden and the Nordic region — and in reducing climate impact.

When plastic is recycled instead of incinerated, and when recycled material replaces fossil-based plastic in new products, significant emissions are avoided. This is how we close the loop: by ensuring that plastic can be reused in new packaging and products of the same high quality, keeping resources in circulation.

We also make recycled plastic raw materials available to the market — enabling a truly circular plastics economy in practice.

Our priority sustainability areas

Tracking our climate impact

By managing and recycling the plastic that reaches our facility, we directly help reduce the climate footprint of packaging manufacturers — and strengthen Sweden’s ability to reach its climate and recycling targets.

Since 2020, we have published an annual climate report in accordance with the Greenhouse Gas (GHG) Protocol guidelines. This enables us to transparently present the climate impact across different parts of the value chain and track progress towards our climate goals.

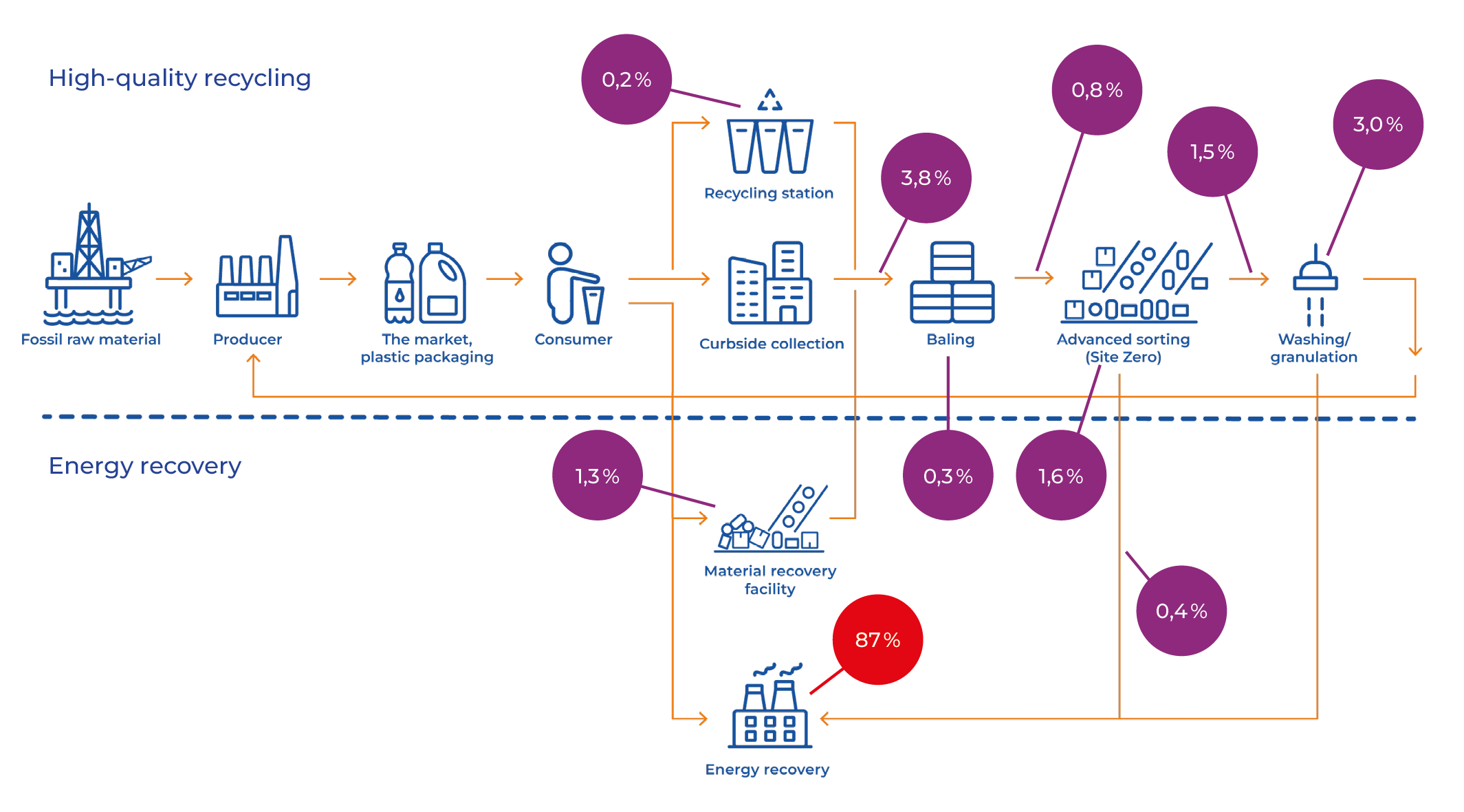

Emissions in the recycling system

Collecting and recycling plastic packaging has a certain climate impact. But by avoiding incineration, we prevent emissions that far exceed the footprint of the recycling system itself. Every piece of plastic packaging we divert from incineration to recycling delivers a direct climate benefit.

The largest share of the recycling system’s climate impact comes from the incineration of plastic packaging that currently cannot be recycled — about 87 percent. Some of this packaging is not designed for sorting or recycling and is therefore discarded during the sorting process. Other packaging can be sorted, but no viable recycling solution exists yet. We are actively working to change this.

In comparison, the emissions generated in the rest of the system are relatively small — that is, all activities required for the collected packaging to become new plastic raw material.

Upstream, this mainly involves transport during the collection stage — from recycling stations or property-based collection to our sorting facility in Motala.

Downstream, the largest share of emissions comes from our recycling customers’ energy use for washing and granulating the plastic, followed by transport to their facilities.

With Site Zero, we can sort the majority of all plastic packaging found on the Nordic market. However, for the recycling system to deliver the greatest possible climate benefit, efforts are needed throughout the entire value chain — from packaging being designed for recycling, to consumers sorting it correctly, and to subsequent sorting and recycling being carried out as resource-efficiently as possible.

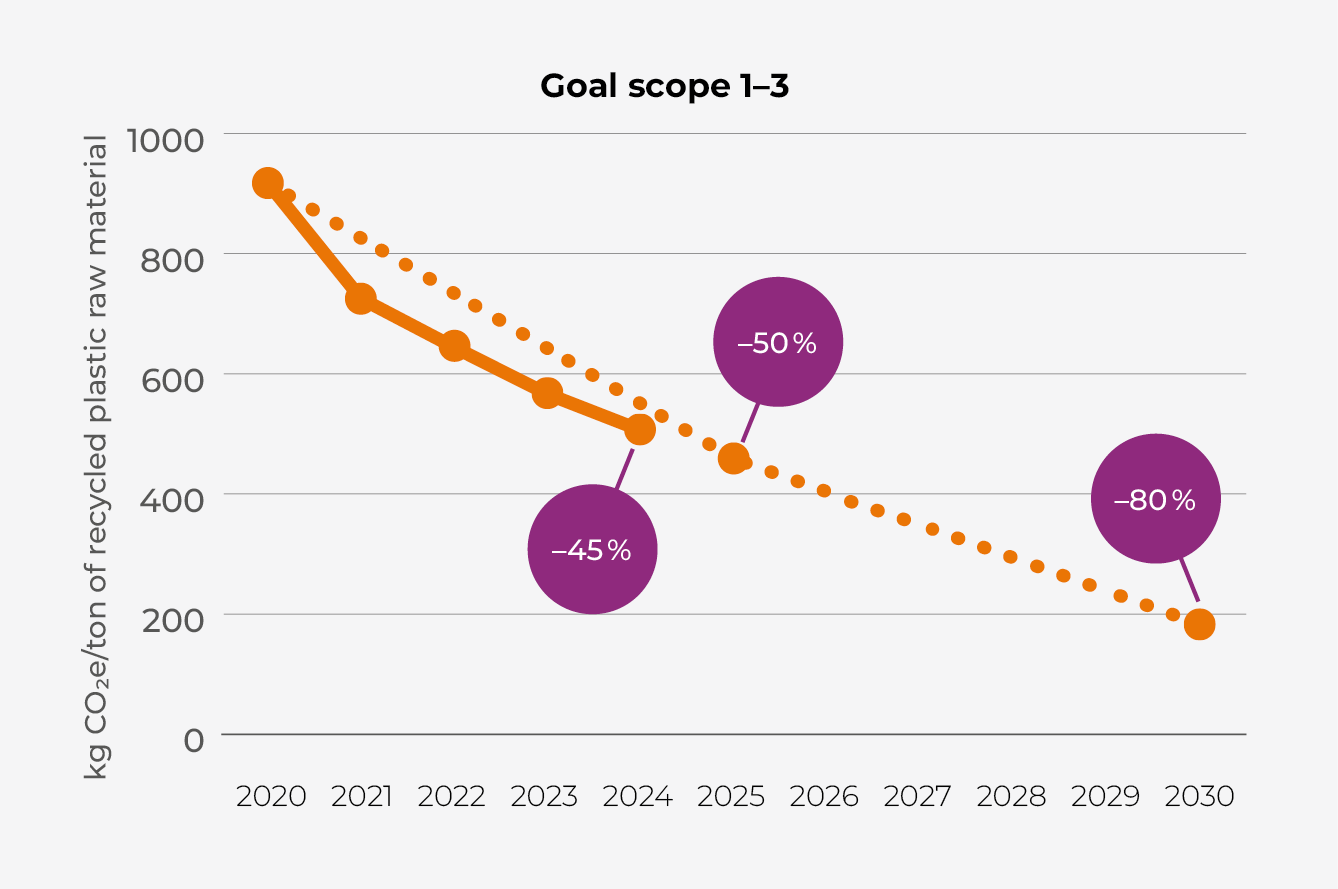

Progress towards our 2025 climate target

The results for 2024 show that the climate impact per tonne of recycled plastic has decreased by 45 percent compared with our base year, 2020.

This means that development is moving in the right direction — and that we are well on our way to achieving our interim target for 2025: a 50 percent reduction in emissions per tonne of recycled plastic.

Our target: Reduce climate-impacting emissions from plastic packaging recycling by 80 percent by 2030, compared with 2020, per tonne of recycled material.

The target includes Scope 1–3 emissions from Svensk Plaståtervinning’s operations.

Our interim goal for 2025 is a 50 percent reduction compared with the base year, 2020.

High-quality material recycling

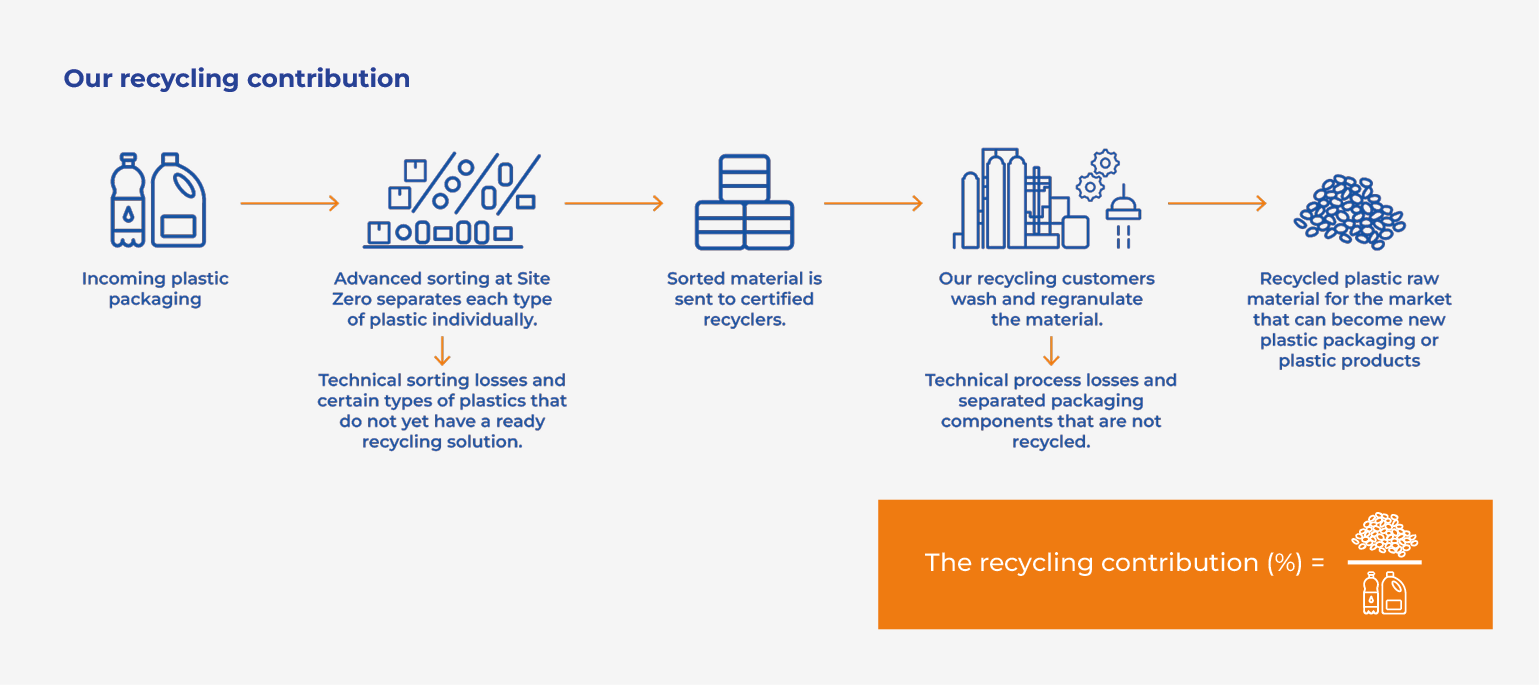

Introducing the Recycling Contribution

Since January 1, 2024, we have adopted a new, streamlined role and business model. We are now solely responsible for sorting and recycling plastic packaging from households.

Previously, our remit also included the collection system, and we measured and reported what was known as the recycling rate.

With our new role and responsibilities, the way we measure and report our results has changed. We now measure the share of plastic packaging received at Site Zero that ultimately becomes recycled raw material — in accordance with the EU definition. We call this the Recycling Contribution.

The Recycling Contribution reflects our role in the resource-efficient management of material that is sorted at our facility and recycled by us or our partners. The concept provides a clearer picture of our contribution to Sweden’s national recycling targets. At the national level, the recycling rate is measured in aggregate for household packaging, commercial packaging, and deposit bottles in each EU country.

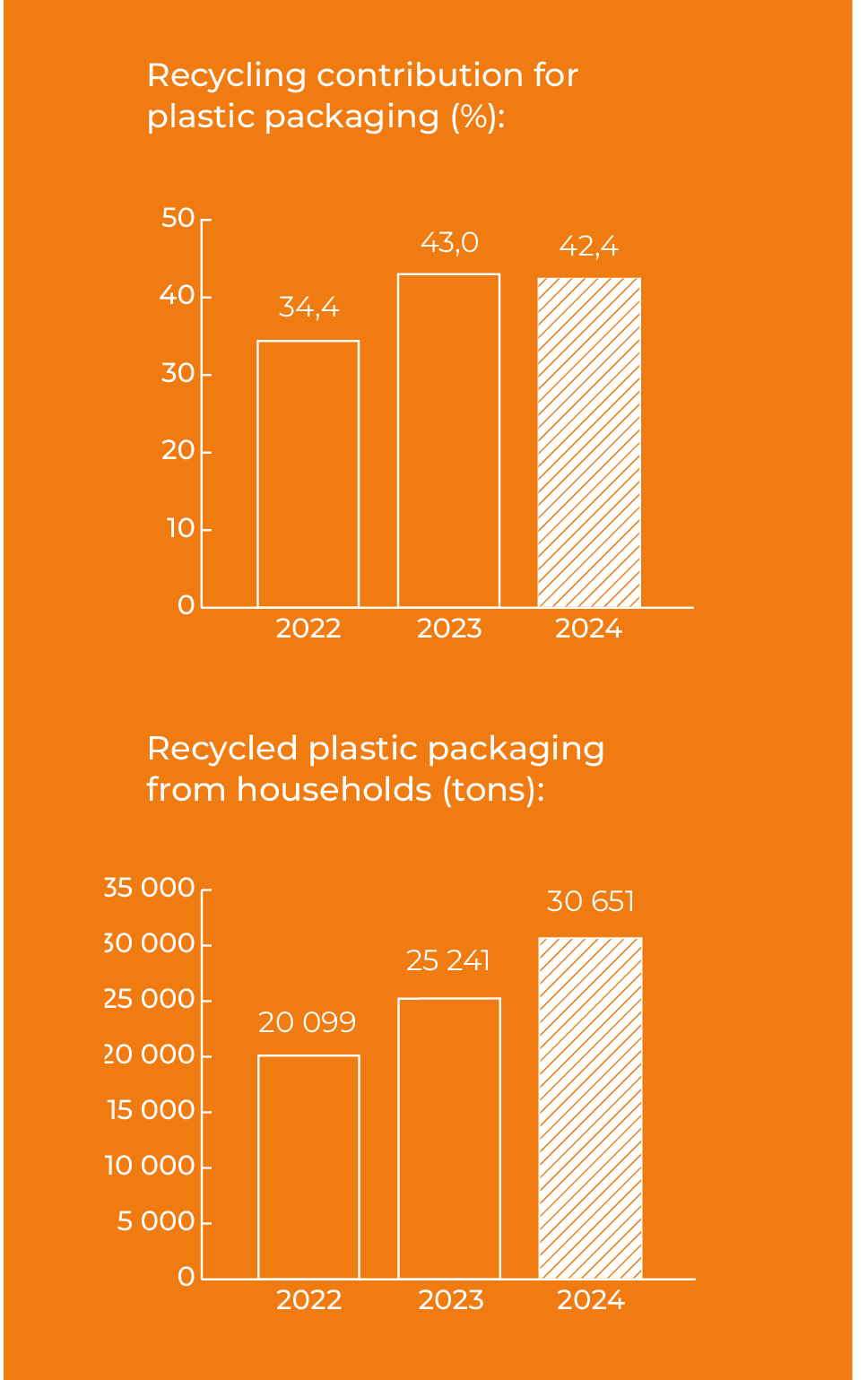

Strong growth in recycling performance

In 2024, we recycled 30,651 tonnes of plastic packaging — an increase of approximately 5,400 tonnes, or just over 20 percent, compared with the previous year.

The Recycling Contribution from Svensk Plaståtervinning’s operations in 2024 was 42.4 percent.

To track progress and enable comparison over time, we have also calculated the Recycling Contribution for 2023 and 2022. The increase between 2022 and 2023 is largely due to Site Zero becoming operational in 2023, which made it possible to sort a greater variety of plastics with higher efficiency.

New markets are emerging for several types of plastic that were previously not recycled, and additional recycling facilities for these materials are now being built across Europe. In the coming years, we therefore expect to see further increases in the Recycling Contribution..

80-80-80

Contributing to the EU’s 2030 recycling target

The EU’s target is to achieve a 55 percent recycling rate for plastic packaging by 2030.

In practice, for member states to reach this target, collection, sorting, and recycling must each operate at an efficiency level of over 80 percent. This means that 80 percent of plastic packaging must be collected, 80 percent of the collected packaging must be sorted for recycling, and at least 80 percent of the sorted plastic must ultimately become recycled raw material. This principle is known as the 80–80–80 rule.

At Svensk Plaståtervinning, we are responsible for the latter two stages — sorting and recycling. Our goal is to contribute to achieving Sweden’s national target for household plastic packaging. In the long term, this means that our Recycling Contribution needs to reach 64 percent (80 × 80).

Designing for recyclability

The design of plastic packaging placed on the market is crucial to how well it can be sorted and recycled. It needs to be made from a type of plastic that can be recycled, but it also needs to be designed so that labels, printing ink, and glue, for example, do not hinder sorting or the subsequent recycling process.

One ongoing challenge is the large proportion of laminate packaging, which consists of several thin layers of different plastics glued together. This type of packaging often plays an important role in effectively protecting and extending the shelf life of packaged foods, but the mixture of different plastics makes it less desirable on the recycling market and difficult to recycle. However,

there are positive developments in this area, with several manufacturers having developed more recyclable alternatives to their laminate packaging.

Traceability

Traceability throughout the value chain is a cornerstone of our operations and a key element in the transition to circular material use.

By going beyond legal requirements, we aim to raise standards across the waste and recycling industry, promote transparency, and ensure that collected plastic is genuinely recycled in a sustainable way. This creates trust and accountability for both producers and consumers.

We have a robust and transparent traceability process that covers every stage of the system.

Ensuring traceability across the value chain

Materials collected by our sorting customers are transported via baling and transshipment stations to our sorting facility in Motala.

Weight and quality are checked both before shipment and upon arrival. After sorting, the separated materials are sent directly to our European recycling partners, where they are weighed once again.

Our recycling customers are carefully selected through a thorough review process based on a set of fundamental requirements. A key part of our traceability policy is to work directly with operators who carry out the recycling themselves — without intermediaries.

All recyclers must be located within the EU and therefore comply with EU waste legislation and the waste hierarchy. They are also required to hold RecyClass certification, an initiative that recognises recyclers with high standards for material handling in line with EU standard EN 15343:2007. The certification places strong emphasis on traceability throughout the entire value chain.

Before entering into any potential collaboration, tests are carried out to ensure that our material performs well in the intended recycling process and that recycling efficiency remains high.

Even during test runs, both parties sign an agreement to minimise the risk of materials being handled incorrectly.

New partners must comply with our Code of Conduct before entering into an agreement. We also advocate long-term contracts to ensure continuity and stability.

A safe and stimulating work environment

Our employees are among our most valuable resources.

Without their commitment, expertise, and daily efforts, our operations would come to a standstill. Ensuring a safe and healthy working environment is therefore one of our highest sustainability priorities.

Svensk Plaståtervinning has grown rapidly since the opening of Site Zero, and our continued journey will create even more job opportunities. This development affects us in many ways — not least in how we operate as an employer. Our work environment initiatives aim to create a stimulating workplace where safety always comes first, both in our physical operations and within the organisation as a whole.

Systematic work environment management

As we continue to grow, new demands are placed on us as an employer.

Our main focus is to provide a safe workplace supported by clear structures within our systematic work environment management.

This includes regular safety inspections, risk assessments, work environment training, and incident investigations, among other activities.

Diversity, inclusion, and equality

We employ people with diverse backgrounds and skills, and we place great emphasis on being an inclusive, safe, and welcoming workplace.

We take great pride in the diversity within our company.

Our workforce consists of 19 percent women and 81 percent men, while the management team comprises 67 percent women and 33 percent men.

Through recruitment and workforce planning, we actively strive to further increase diversity. We also conduct an annual salary review to ensure that no unjustified pay gaps exist within the organisation.

Promoting diversity and inclusion in practice

Within the area of diversity and inclusion, we have launched a project aimed at increasing the proportion of women in production.

This is being achieved through a long-term, intentional recruitment strategy and strengthened cultural and values-based initiatives.

As part of our inclusion efforts, we also collaborate with Samhall and the Swedish Public Employment Service through local job initiatives. In this way, we provide opportunities for people who are further from the labour market to take part in internships — and, in many cases, find a pathway into working life.

This is a concrete example of how we strive to contribute to a more open and sustainable society, while at the same time strengthening our business with new perspectives and skills.

![fc iso9001 14001 45001_swedac-white[9]](https://www.svenskplastatervinning.se/wp-content/uploads/fc-iso9001-14001-45001_swedac-white9.png)